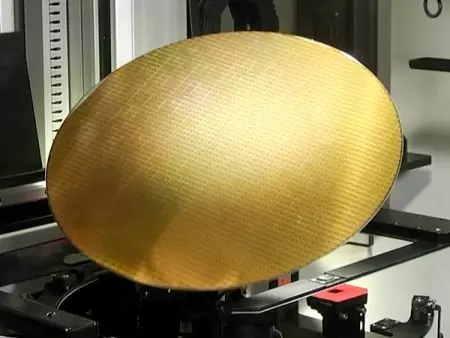

Automatic Wafer Optical Microscope Inspection Equipment

OMM-3200

Automatic Wafer Inspection

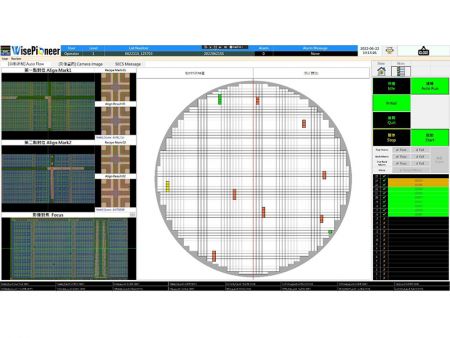

The main functions of the automatic wafer optical microscope inspection equipment is to perform wafer inspection according to customer requirements, replacing manual operation, improving wafer inspection speed and accuracy, reducing false detection rates, and automatically reporting, storing, and analyzing data through SECS to meet the requirements of intelligent and automated production lines. This effectively reduces customer inspection costs and completes comparison with the end customer's inspection results, as well as various types of inspection methods (AQL sampling, multi-zone sampling, strict inspection), and customized settings for the Pad inspection area morphology (geometric outline).

Features

- Optional single or double wafer cassette automatic loading system.

- With dimension measurement and AOI + AI defect detection function.

- Customizable manual equipment can be transformed into automated equipment.

- Support SECS / GEM communication.

Applications

Wafer Size: 8 inch, 12 inch

Objective Magnification: 5X, 10X, 20X, 50X, 100X (Optional)

Auto Focusing: Imaging or Optical Confocal

Software Function: OCR, Recipe Setup, Defect AOI

Equipment Size: 1900mm (L) x 1704mm (W) x 1800mm (H)

- Gallery

Automatic Wafer Optical Microscope Inspection Equipment | Made in Taiwan Intelligent Process Equipment | Shuz Tung

Based in Taiwan since 1979, Shuz Tung Machinery Industrial Co., Ltd. is a manufacturer of intelligent process equipment. It's main intelligent process equipment include, Automatic Wafer Optical Microscope Inspection Equipment, semiconductor automation equipment, semiconductor metrology and inspection equipment, flat panel display turnkey equipment, TFT-LCD module process whole line equipment and wafer shipper automatic packing and unpacking machines. We offer customized designs for optimal equipment efficiency in high-tech industries. Prioritizing speed of production, quality and environmental friendliness ensures competitive advantage and significant added value.

Established in 1979, with 43 years vast experience and resources in customized equipment manufacturing, and outstanding optical, mechanical, electronic, software, and system integration ability, Shuz Tung Machinery Industrial focuses on the core technologies, including Precision Mold Manufacturing, Laser Repair and Cutting, High Accuracy Bonding (PCB Bonder), Automatic Optical Inspection (AOI), Artificial Intelligence Imaging, and Turnkey Solution for Smart Manufacturing.

Shuz Tung has been providing customers with high quality intelligent process equipment since 1979, both with advanced technology and 30 years of experience, Shuz Tung ensures that each customer's needs are met.