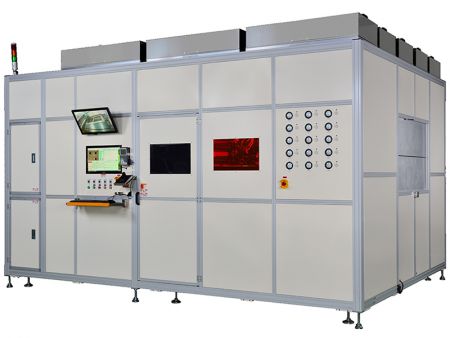

Full-size Inline Equipment for Panel Module Manufacturing

Flat panel display process equipment, full-size integrated production line equipment for the panel module segment, including edge cleaning machines, lead bonding machines, inspection machines, glue dispensing machines, printed circuit board bonding machines, printed circuit board inspection machines, and laser cutting and marking machines, designed, planned, manufactured, and produced.

As a manufacturer of process equipment for flat panel displays, 3D displays, TFT-LCDs, touch panels, OLEDs, and other glass panel sizes, Shuz Tung Machinery provides cleanroom-specific panel processing logistics and storage equipment for G3 ~ G10.5 glass panel sizes. With the use of pick and transfer mechanisms, the company ensures correct storage, handling, and transfer of substrates within EPP boxes, dense packs, or cassettes to each station, thereby improving the production efficiency of its customers' manufacturing lines. The company helps its customers leverage big data analytics to enhance their productivity and competitiveness in the digital era of automotive, 5G communications, IoT, and AI. With its core technology of optical, mechanical, and software system integration, the company offers fully automated production lines for flat panel display modules, including high-density machine board bonding equipment, gluing equipment, edge cleaning machines, external pin bonding machines, inspection machines, printing circuit board bonding machines, printing circuit board inspection machines, and laser cutting machines. The applications of these products include a 65" full-automatic production line for TV modules, ultra-narrow frame module equipment, wearable bonding equipment, small-sized module full-automatic production lines, AOI automatic optical inspection equipment for over-coated films, automatic inspection machines for conductive particles and side gluing, and automatic laser cutting, polarization plate cutting, and repair machines.

Shuz Tung Machinery provides "consulting services, process planning, mechanical design, whole-plant output, installation and commissioning, education and training, trial production, and after-sales service" before setting up a factory. We offer customized whole-plant services from individual equipment to intelligent system integration for customers, providing comprehensive customization solutions.

TFT-LCD and Touch Panel Equipment

- Array ADI / AEI AOI

- Color Filter Repair

- Laser Repair

- Macro / Micro

- Lead Check

- LCM Whole-Plant Equipment

Mask Laser Repair

AOI + Laser Repair

Mask Laser Repair Inspection machine and laser machine (AOI + Laser Repair) for metal mask...

DetailsFull-size Inline Equipment for Panel Module Manufacturing | Intelligent Process Equipment: The Role of Smart Machinery in Automated Systems.

Based in Taiwan since 1979, Shuz Tung Machinery Industrial Co., Ltd. is a manufacturer of intelligent process equipment. It's main intelligent process equipment include, Full-size Inline Equipment for Panel Module Manufacturing, semiconductor automation equipment, semiconductor metrology and inspection equipment, flat panel display turnkey equipment, TFT-LCD module process whole line equipment and wafer shipper automatic packing and unpacking machines. We offer customized designs for optimal equipment efficiency in high-tech industries. Prioritizing speed of production, quality and environmental friendliness ensures competitive advantage and significant added value.

Established in 1979, with 43 years vast experience and resources in customized equipment manufacturing, and outstanding optical, mechanical, electronic, software, and system integration ability, Shuz Tung Machinery Industrial focuses on the core technologies, including Precision Mold Manufacturing, Laser Repair and Cutting, High Accuracy Bonding (PCB Bonder), Automatic Optical Inspection (AOI), Artificial Intelligence Imaging, and Turnkey Solution for Smart Manufacturing.

Shuz Tung has been providing customers with high quality intelligent process equipment since 1979, both with advanced technology and 30 years of experience, Shuz Tung ensures that each customer's needs are met.